Mechinz can offer you an extensive range of engineering services comprising of design, engineering, manufacturing, installation, commissioning and validation of systems & equipment engaged in utilities administering to process industries.

The demand for process heating and temperature control in the industry continues to increase as manufacturers and industrial facilities grow, expand, and seek to improve their existing operations. These process heating systems must perform consistently, safely, and with minimal downtime over time.

Industrial facilities that use plant-wide distributed process systems typically have one of two process systems: steam boilers or thermal fluid heating systems. Boilers were often the default choice in the past, but thermal fluid heating systems are a better solution for many applications, offering improved flexibility, control, and reliability.

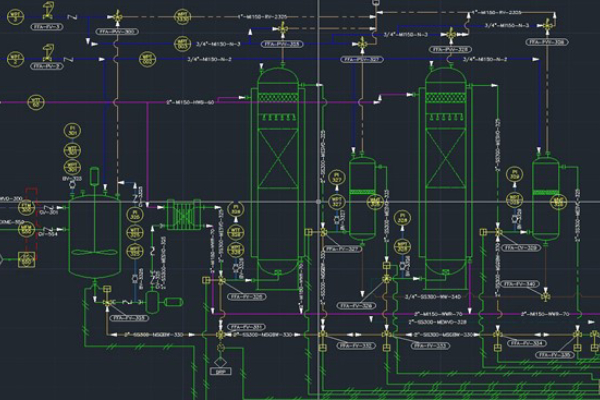

We offer Utilities designs for Steam, Condensate, Compressed Air, Thermic fluid, Effluents, Raw Water, Cooling water & Hot water

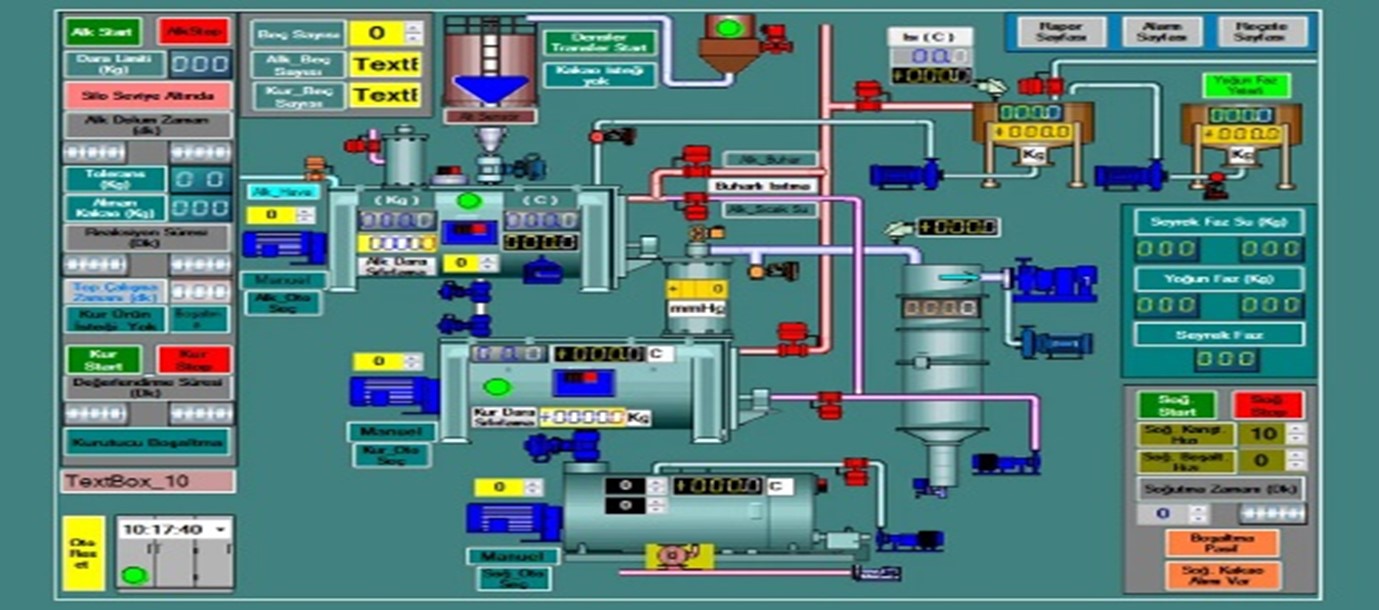

We undertake turnkey projects involving supply of MCC, PLC Control Panels, Drives, Field Instruments, HMI systems, SCADA systems including software development, installation & commissioning of instrumentation & automation projects across diverse industries.

Electrical control panels are a key element of industrial automation. All manufacturing processes and production lines require electrical control panels to protect equipment, increase productivity, reduce down time, and meet safety regulations

a) Detail Engineering

Preparing control philosophy, IO Assignment, Cabinet GA and wiring drawing (System, Marshalling, and Power Distribution Panels)

b) Hardware Design

Cabinet internal layout, cabinet external outline, loop drawings, bill of materials, engineering drawings in e-plan, AutoCAD

c) PLC & SCADA Development

Input Reconciliation, verification, control Narratives, Logic Development, Simple & Complex Loops Customized Screen development of SCADA/HMI from P&ID Cause & Effect, Static and Dynamic graphics development and testing with logic, shape development popup and faceplates.

d) Industry 4.0 / (IoT)

The term Industry 4.0 encompasses a promise of a new industrial revolution—one that marries advanced manufacturing techniques with the Internet of Things to create manufacturing systems that are not only interconnected, but communicate, analyse, and use information to drive further intelligent action back in the physical world

The Internet of Things (IoT) is a network of physical objects that are fitted with sensors, software and other technologies. Connected to the Internet, these ‘things’ are able to exchange real time data with other connected devices and systems over networks. These connected devices combine with automated systems to gather IoT data that can be analysed to assist with tasks or learn how to improve a process

e) Factory Acceptance Testing (FAT) Support

System, Marshalling, Network and Power Distribution Board cabinets GA and wiring verification, functional checks for systems (PLC, HMI & SCADA) quality and workmanship verification.

f) Site Acceptance Testing (SAT) Support

Site Acceptance Testing (SAT) Support and Commissioning, Testing & Integration of the system.

Based upon our observation and client interaction, we study the present process in detail and find out the industry standard with respect to Steam/energy Consumption.

• Sizing & Selection

• Types of Valves & Traps used and to be recommended

• Temperature & Pressure profile at various critical locations.

• Physical measurement of the condensate discharge

• Study & explore the various condensate and Flash Steam Recovery Options

Our Audit Report includes recommendations on short, medium, and long-term measures for energy conservation, along with financial estimates and analysis for their implementation. These recommendations come with databases and fact sheets generated by measurements and tests conducted in your plant and the field. In addition, we offer assistance in implementing and performance monitoring of our energy conservation proposals which is achieved by the expert services of our engineers and the training of the user’s operators.

• Exploration of maximum energy savings.

• Study on how to enhance process efficiency by decreasing process downtime

• Failure analysis of particular steam component of plant and root cause analysis system.

• Involvement of plant team from utility, process for awareness of energy conservation in steam engineering

• Energy savings subjected to implementation of recommendations in energy audit report.

The concept of energy efficiency revolves around reducing energy consumption without compromising with the actual facilities used. Generally, the conventional products are replaced with more sophisticated ones such as a normal filament bulb replaced with energy efficient LED light. The techniques employed under this discipline may result in energy savings as well as financial cost savings. Sustenance is maintaining these practices in the long run.

Manufacturers and plant operators are always looking out to achieve efficiencies in terms of cost and operations. By refocusing engineering objectives on layout optimization and lean design principles, we enable manufacturers to improve plant sustainability and optimize Operational expenditures

We bring end-to-end manufacturing and plant maintenance services expertise in delivering plant sustainability and enhancing operational efficiency.